Blog

What Goes Into a Professional Concrete Pour? A Step-by-Step Breakdown

To most homeowners, a concrete pour looks simple: concrete arrives, it gets poured, and the surface is finished. In reality, a professional concrete pour is a carefully planned process where every step affects strength, appearance, and longevity—especially in a climate like Denver.

At Wally’s Concrete, we believe an informed homeowner makes better long-term decisions. Here’s a clear, step-by-step look at what actually goes into a professional concrete pour—and why quality work lasts for decades.

Step 1: Site Evaluation & Planning

Every successful concrete project starts before any digging begins.

We evaluate:

-

Soil conditions and slope

-

Drainage and water flow

-

Load requirements (vehicles, structures, foot traffic)

-

Weather timing and temperature

Skipping this step is one of the biggest causes of premature concrete failure.

Step 2: Excavation & Base Preparation

The base is the foundation of the entire project—literally.

Professional base prep includes:

-

Excavating to proper depth

-

Removing soft or unstable soil

-

Installing compacted gravel or road base

-

Ensuring even, stable support

In Colorado, improper base preparation is a leading cause of cracking and settling.

Step 3: Forming the Concrete

Forms shape the concrete and control thickness, edges, and slope.

This step ensures:

-

Clean, straight lines

-

Proper water runoff

-

Correct slab thickness throughout

-

Protection against spreading or sagging

Good forming is key to both appearance and performance.

Step 4: Reinforcement Installation

Concrete is strong in compression—but reinforcement improves durability and crack control.

Depending on the project, we may use:

-

Rebar

-

Wire mesh

-

Fiber reinforcement

Reinforcement helps concrete withstand freeze-thaw cycles, heavy loads, and soil movement.

Step 5: Pouring the Concrete

Timing matters. Concrete must be poured at the right temperature and consistency.

Professional pouring includes:

-

Proper concrete mix for climate conditions

-

Even distribution to prevent weak spots

-

Avoiding overworking the surface

This is where experience makes a major difference.

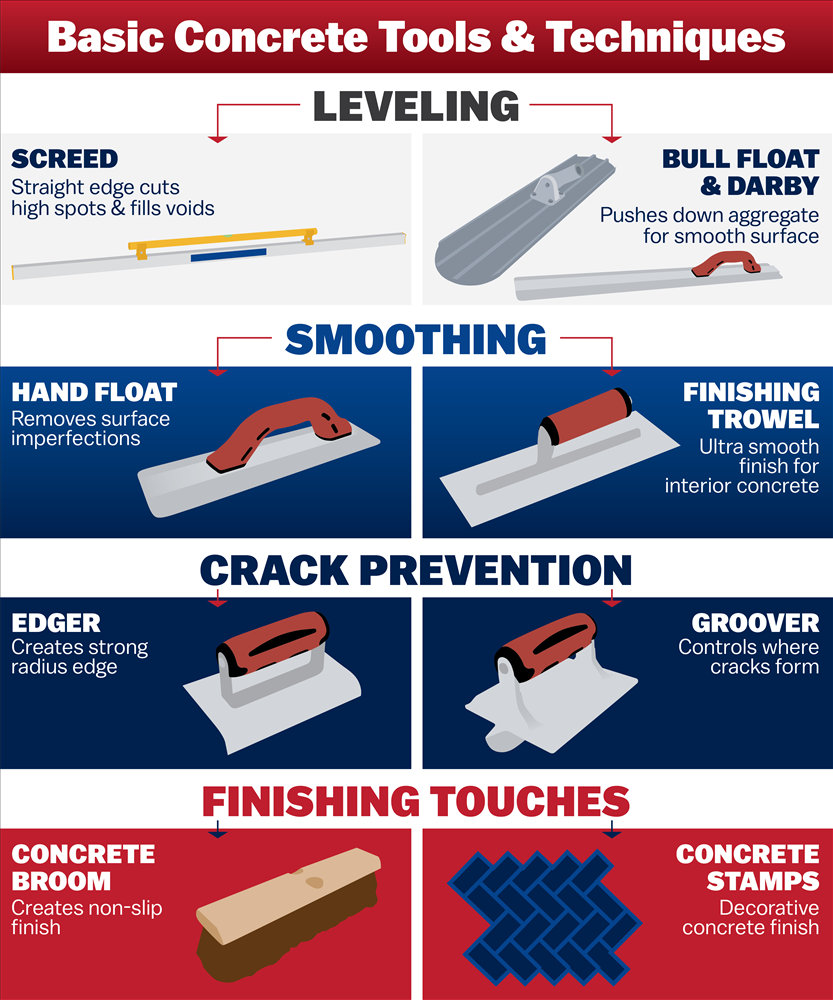

Step 6: Finishing the Surface

Finishing determines both function and appearance.

Common finishes include:

-

Broom finish for traction

-

Smooth trowel finish

-

Decorative or stamped textures

The goal is a surface that looks great and performs safely year-round.

Step 7: Control Joints & Crack Management

Concrete will crack—it’s normal. Control joints help cracks occur where they’re supposed to, not randomly.

Proper joint placement:

-

Improves appearance

-

Reduces long-term damage

-

Extends slab lifespan

This is a detail many inexperienced installers overlook.

Step 8: Curing the Concrete

Curing is one of the most critical—and misunderstood—steps.

Proper curing:

-

Increases concrete strength

-

Reduces surface cracking

-

Improves long-term durability

Concrete doesn’t just “dry”—it cures over time. Rushing this step weakens the slab.

Why Professional Installation Matters

A professional concrete pour:

-

Lasts longer

-

Performs better in extreme weather

-

Requires less maintenance

-

Saves money over time

Cut corners at any step, and problems show up fast—especially after a few Colorado winters.

Built Right the First Time

At Wally’s Concrete, we follow every step carefully because we build concrete to last—not just to look good on day one.

Whether it’s a driveway, patio, sidewalk, or slab, professional process makes all the difference.

Planning a Concrete Project?

If you’re considering new concrete or replacing old surfaces, we’re happy to walk you through the process and provide a clear, honest estimate.

📞 Contact Wally’s Concrete today to get expert workmanship built for Colorado conditions.

Wally’s Concrete is a trusted concrete contractor proudly serving Denver and the surrounding Front Range communities. We specialize in residential and commercial concrete solutions built to handle Colorado’s climate, soil conditions, and long-term wear.